By David South, Development Challenges, South-South Solutions

South-South trade is the great economic success story of the past decade. World Trade Organization (WTO) (www.wto.org) figures show South-South trade accounted for 16.4 percent of the US $14 trillion in total world exports in 2007, up from 11.5 percent of the total in 2000. While the global economic crisis has slowed things down, the overall trend is firmly established.

Trade between China and Africa has surged over the past decade since China joined the WTO in 2001, from around US $10 billion in 2000 to US $73.3 billion in 2007, registering a year-on-year increase of 32.2 percent. In 2008, it soared by 44.1 percent to reach a record high of US $106.84 billion, registering a year-on-year increase of 45.1 percent, according to Zhang Yongpeng of the Institute for West Asian and African Studies (IWAAS).

In the southern Chinese city of Guangzhou (http://en.wikipedia.org/wiki/Guangzhou) , a trading hub nicknamed “Africa Town” has emerged since 1998. A conglomeration of buildings around the Xiaobei road in Yuexiu district of the city, it has been equated to the famous Chungking Mansions of Hong Kong (http://en.wikipedia.org/wiki/Chungking_Mansions) . There are officially 20,000 African traders and entrepreneurs in the city of 18 million, but unofficial estimates put the number at more than 100,000. This African trading hub has emerged to the benefit of both the Chinese and Africans. It is a coming together of small traders matching Africa’s strong demand for consumer goods with China’s manufacturing powerhouse.

The traders export generators, toys, mopeds, construction equipment and other products back to Africa. The traders act as go-betweens, bringing their local knowledge of African market demands to the Chinese manufacturers.

Citizens from over 19 African countries are represented, the majority from Nigeria.

“Almost 90 per cent of goods in African markets come from China, Thailand and Indonesia,” Sultane Barry, president of Guangzhou’s Guinean community, told the Globe and Mail newspaper.

Barry has an entire floor for business in a 35-storey building packed with shops, offices, freight-forwarding companies, African restaurants, hairdressers and furnished apartments for rent by the week.

“We’re not here for fun,” said Ibrahim Kader Traore, an entrepreneur from Ivory Coast. “We work hard and do well. In Abidjan, people still swear by France, where you might be able to save US $13,000 over 25 years; in China, you can have US $130,000 in just five years.”

A trading success story, the hub has run into problems over visas and the upcoming November Asian Games in Guangzhou, which is increasing identity checks.

“I sell more than 50 per cent of the output of my brother-in-law’s TV factory to Africans,” one saleswoman told the Globe and Mail. “We need them and I’m worried there are going to be fewer of them.”

Brought together by trade and mutual interest, both communities still have much to learn about each other. Relations have had their ups and downs and Africans can face discrimination.

But the trading relationship is teaching both sides important lessons. “The arrival of the Africans taught the Chinese how to look for business opportunities,” said Barry. “The secretaries we had here didn’t speak a word of English. Our presence started a craze for learning languages: English and French. The Chinese didn’t know the basic rules of international trade. They knew nothing about documentary credit. They paid for everything cash in hand.

“The Chinese people will soon realize that it’s better for business to deal directly with ordinary Africans.”

And the pressure is on to see who will keep trading relations with Africa positive. “The door to the Chinese market has only opened a crack, mostly because visa requirements are so tough,” said Zango, a trader from Mali.

Published: July 2010

Resources

1) A Financial Times report on Africa-China trade in 2010. Website: http://www.ft.com/reports/africa-china-trade-2010

2) An article about “Africa Town” from the official Guangzhou website. Website: http://www.lifeofguangzhou.com

3) Trade Winds: Guangzhou’s African Community by Graeme Nicol is a photo book about the community. Website: http://graemenicol.com/?page_id=115

https://davidsouthconsulting.org/2022/06/02/afghanistans-juicy-solution-to-drug-trade/

https://davidsouthconsulting.org/2022/11/02/african-online-supermarket-set-to-boost-trade/

https://davidsouthconsulting.org/2022/11/21/chinese-trade-in-angola-helps-recovery/

https://davidsouthconsulting.org/2022/04/12/djibouti-re-shapes-itself-as-african-trade-hub/

https://davidsouthconsulting.org/2022/10/05/women-empowered-by-fair-trade-manufacturer/

https://davidsouthconsulting.org/2022/06/16/women-mastering-trade-rules/

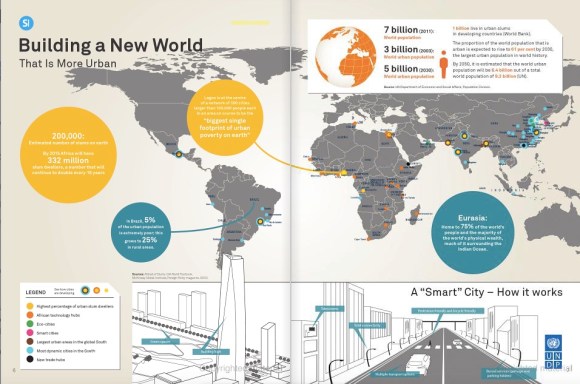

Development Challenges, South-South Solutions was launched as an e-newsletter in 2006 by UNDP’s South-South Cooperation Unit (now the United Nations Office for South-South Cooperation) based in New York, USA. It led on profiling the rise of the global South as an economic powerhouse and was one of the first regular publications to champion the global South’s innovators, entrepreneurs, and pioneers. It tracked the key trends that are now so profoundly reshaping how development is seen and done. This includes the rapid take-up of mobile phones and information technology in the global South (as profiled in the first issue of magazine Southern Innovator), the move to becoming a majority urban world, a growing global innovator culture, and the plethora of solutions being developed in the global South to tackle its problems and improve living conditions and boost human development. The success of the e-newsletter led to the launch of the magazine Southern Innovator.

This work is licensed under a

Creative Commons Attribution-Noncommercial-No Derivative Works 3.0 License.

ORCID iD: https://orcid.org/0000-0001-5311-1052.

© David South Consulting 2022

You must be logged in to post a comment.