By David South, Development Challenges, South-South Solutions

Around the world, large-scale agriculture relies on the use of chemical fertilizers. But increasing expense and decreasing supply of fertilizer is driving up the cost of food, and in turn contributing to the overall food crisis.

According to a soon-to-be-released UN report, prices have shot up and will stay high for at least three years. Prices have almost doubled and in some cases risen by 500 percent over 15 months.

The fertilizer crisis is caused by several factors. Anhydrous ammonia, which is the source of nearly all nitrogen fertilizer, needs natural gas, and the price of gas has risen sharply. Other fertilizer ingredients like phosphorous, potassium and potash are also increasingly expensive. Fertilizer needs to be transported long distances to get to farmers, so costs have risen with the soaring price of oil. And finally, the rise in demand for food has put the price of fertilizer up, as countries hoard supplies for themselves.

The 1960s ‘Green Revolution’ in agriculture made developing-world farmers dependent on supplies of fertilizers, pesticides and artificial irrigation. Monoculture cash crops became the norm. Yields were doubled, but at the expense of using three times as much water by accessing groundwater using electric pumps. This and fertilizer pollution has caused widespread damage to soil and water. In India, for example, 57 per cent of the land is degraded, according to Tata Energy Research.

In Cambodia, farmers are reaching back to past practices for answers to the fertilizer crisis. One is to go organic. Taking this approach has many health and environmental advantages – and, best of all for farmers, it keeps costs down.

Khim Siphay, a Cambodian farmer, has found he gets bigger crops of rice and vegetables while paying a lot less for fertilizers.

“Using pesticide or fertilizers kills important insects, and causes the soil to become polluted,” he told Reuters. “I use compost and it helps keep the soil good from one year to another. All of my family members help make the compost.”

The push to organic methods for Cambodia’s 13 million people relying on agriculture for a living comes from a non-governmental organization, the Cambodian Center for Study and Development in Agriculture (CEDAC). It has successfully moved to organic methods, starting from just a handful of 28 farmers in 2000, to the current 60,000 – and received an endorsement from the Cambodian Ministry of Agriculture.

CEDAC says farms using the organic methods have been able to increase rice yields per hectare, while the seeds needed have fallen by 70 to 80 percent. By using a “System of Rice Intensification”, the mostly small-scale farmers are able to get more out of the land, with less labour. Add to that the fact that organic rice gets a premium price on world markets, and the result for the farmers has been a rise in income from US $58 to US $172 per hectare.

“The important point of organic farming is that farmers don’t need to spend money on fertilizers and pesticide so they spend less money on farming,” said CEDAC official Yang Saing Koma.

“They can sell the produce for a higher price. Also they can avoid being infected by pesticides and they will be healthier. It is also good for the environment,” he said.

Rice and other produce can be used to feed chickens to produce organic poultry and eggs – another bonus for farmers looking to raise the value of their produce.

“I started doing organic farming outside my rice paddy, but then I noticed production was double, so in the next season, I decided to grow organically on all of my land,” said farmer Ros Meo. “I spend less money now and I can grow more and I am not sick as I was before, my health is now good.”

Going organic in Cambodia is something that is becoming more attractive to the country’s growing middle class, and the government hopes the country will gain a reputation as an organic producer.

Another approach to cheap fertilizer comes from Caracas, Venezuala. Marjetica Potrc, an artist and architect who works closely with impoverished communities, has come up with a “dry toilet” which collects human waste and converts it to fertilizer.

Developed after spending six months in the barrios of Caracas, the dry, ecologically safe toilet was built on the upper part of La Vega barrio, a district in the city without access to the municipal water grid. It is a place where about half the population receives water from municipal authorities no more than two days a week.

Published: March 2014

Resources

- South African company Eat Your Garden: It provides urban dwellers and food businesses with their own food gardens bursting with juicy and tasty foods whilst at the same time reducing carbon footprints, and creating employment and provide training, helping poverty alleviation.

Website: http://www.eatyourgarden.co.za/ - Soil Association: The organization that establishes the standards necessary for food to be called organically grown.

Website: http://www.soilassociation.org/ - Patrick Kamzitu, a farmer in Malawi, on the impact of fertilizer prices:

Website: www.guardian.co.uk/environment

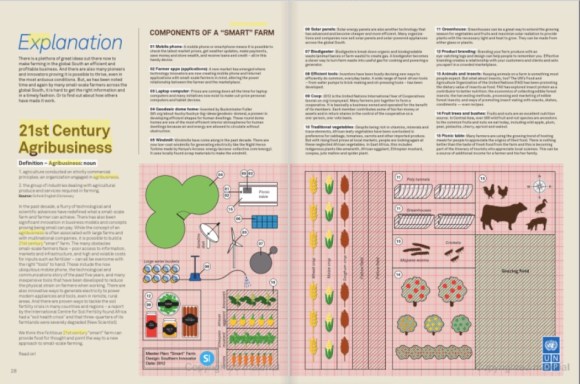

https://davidsouthconsulting.org/2022/11/21/agribusiness-food-security/

https://davidsouthconsulting.org/2022/10/10/cheap-farming-kit-hopes-to-help-more-become-farmers/

https://davidsouthconsulting.org/2022/11/23/kenyan-farmer-uses-internet-to-boost-potato-farm/

https://davidsouthconsulting.org/2022/10/21/a-new-african-beer-helps-smallholder-farmers/

https://davidsouthconsulting.org/2021/11/09/pocket-friendly-solution-to-help-farmers-go-organic/

https://davidsouthconsulting.org/2022/10/26/perfume-of-peace-helps-farmers-switch-from-drug-trade/

https://davidsouthconsulting.org/2022/11/23/putting-worms-to-work/

https://davidsouthconsulting.org/2022/10/17/small-scale-farmers-can-fight-malaria-battle/

https://davidsouthconsulting.org/2021/03/05/southern-innovator-issue-3/

https://davidsouthconsulting.org/2021/03/05/southern-innovator-issue-5/

https://davidsouthconsulting.org/2022/02/10/urban-farmers-gain-from-waste-water/

Development Challenges, South-South Solutions was launched as an e-newsletter in 2006 by UNDP’s South-South Cooperation Unit (now the United Nations Office for South-South Cooperation) based in New York, USA. It led on profiling the rise of the global South as an economic powerhouse and was one of the first regular publications to champion the global South’s innovators, entrepreneurs, and pioneers. It tracked the key trends that are now so profoundly reshaping how development is seen and done. This includes the rapid take-up of mobile phones and information technology in the global South (as profiled in the first issue of magazine Southern Innovator), the move to becoming a majority urban world, a growing global innovator culture, and the plethora of solutions being developed in the global South to tackle its problems and improve living conditions and boost human development. The success of the e-newsletter led to the launch of the magazine Southern Innovator.

This work is licensed under a

Creative Commons Attribution-Noncommercial-No Derivative Works 3.0 License.

ORCID iD: https://orcid.org/0000-0001-5311-1052.

© David South Consulting 2023

You must be logged in to post a comment.