By David South, Development Challenges, South-South Solutions

One thing is ubiquitous to every country, community and society: garbage. It’s a social and environmental problem, but far from being mere waste, rubbish has its uses. This by-product of the goods and foods consumed can also be a source of fuel. As such it has many advantages, including providing free fuel to cash-strapped households, independence from unreliable municipal services and a way to dispose of waste.

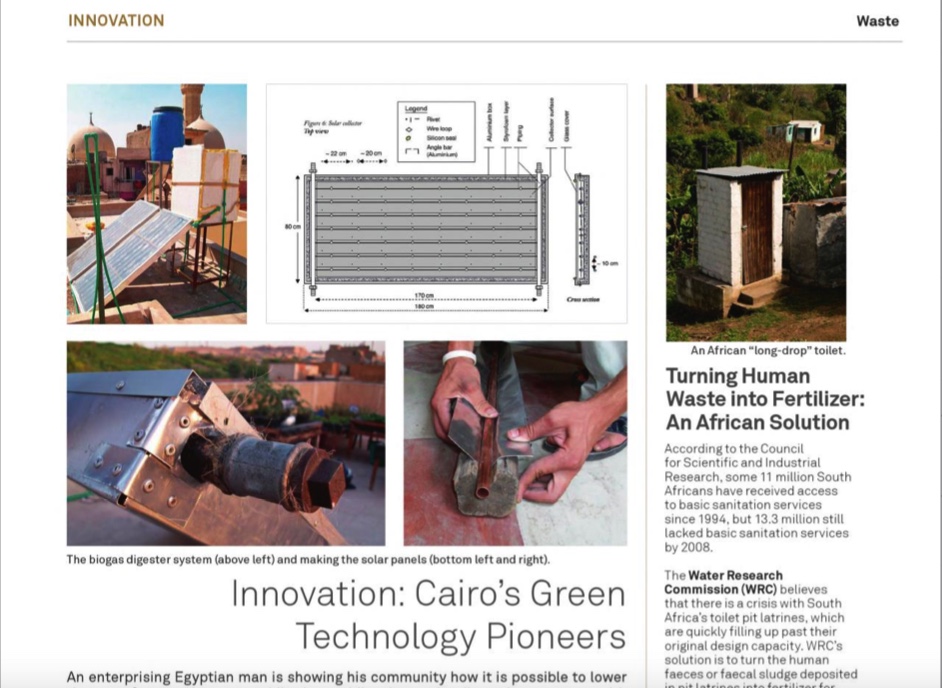

An enterprising Egyptian man is showing his community how it is possible to lower the cost of gas and hot water while also avoiding the service disruptions common with municipal utilities. In the process, he is pioneering a local green innovation model that can be replicated elsewhere.

Biogas (http://en.wikipedia.org/wiki/Biogas) generators — which can transform organic household waste into fuel — have been very successful in India and China. It is estimated there are 20 million small-scale urban biogas digesters in China and 2 million in India.

Hanna Fathy’s roof in the Manshiyet Nasser neighbourhood, home to the Coptic Christian Zabaleen community of Cairo – the city’s traditional garbage collectors and recyclers – is now a utility system, providing biogas and hot water.

The area is made of narrow streets and makeshift houses. Residents live cheek-by-jowl in a neighbourhood that is home to tens of thousands of people.

The community was badly hit when the 300,000 pigs the Christian residents have kept for the past 30 years to eat Cairo’s vegetative waste — an effective garbage-disposal system — were slaughtered under government orders to prevent the spread of swine flu (H1N1) (http://en.wikipedia.org/wiki/Swine_influenza).

One woman told U.S. National Public Radio about the hard life in the neighbourhood: “I’m working all the time. My hands get dirty, there’s no water. The price of food is too high. The gas has gone up to seven pounds (US $1.28) a bottle, so it’s expensive to heat.

“Everything is so expensive, and I have to live like this?” she said.

Fathy plops kitchen scraps, stale tea and tap water into a jug which he pours into a homemade biogas maker on the roof of his house. The stew of waste mixes with water and a small quantity of animal manure used to start the process, and overnight makes biogas, which is then used for cooking. The digester is able to provide an hour’s worth of cooking gas a day in winter months, and two hours in the summer, from around two kilograms of waste. The remaining waste by product becomes liquid organic fertilizer for the garden.

Fathy has been developing the biogas digester with the NGO Solar Cities (http://solarcities.blogspot.com), which provides designs, technical advice and support to Cairo citizens keen to embrace green technologies.

What is interesting is not only the technology but how that technology is being developed. The approach is to innovate and adapt the technology to local resources and skills. This increases the chances of take-up and buy-in.

The designs for the digesters and heaters have evolved through experimentation, brainstorming and availability of local materials.

Each biogas system costs about US $150 for materials, a cost that is being picked up right now by donations. Solar Cities believes there are only eight biogas digesters in Egypt so far, most built in 2009.

Solar Cities’ founder, Thomas Culhane, points out many urban dwellers do not believe they can generate biogas and associate it with rural systems that use animal manure. But the abundance of urban kitchen waste is in fact an excellent source material for biogas.

Culhane believes the biogas digesters are an excellent solution to two problems: the vast quantities of garbage piling up in Cairo, which has had its traditional disposal system disrupted by the slaughter of the pigs, and the city’s emissions of greenhouse gases that contribute to climate change.

Fathy has one goal: to be completely self-sufficient. He has been also prototyping a solar heater on his roof as well as the biogas digester. The solar water heater makes use of items that can be easily found: it recycles black garbage bags, has an aluminium frame and a glass cover. The whole thing rests on a Styrofoam block and uses copper tubes. The water is stored in a bright blue barrel.

Biogas, solar power and other forms of green energy face many obstacles if it is to expand further in Egypt. The average cost of each unit will need to come down to match the income of the users and compete with the government-subsidized energy sector.

Fathy has also found neighbours are skeptical and can’t believe biogas can be made this way.

Another man, Hussain Soliman, had both a solar water heater and biogas digester on the roof of his apartment building before the crumbling building collapsed.

The complete solar water heating system designed by Solar Cities can be assembled for under US $500. It uses two 200-litre recycled industrial shampoo barrels for the holding tank and back-up water supply. The solar panels need to be kept clean from dust every week, but other than that, Culhane insists the heaters require little maintenance.

Now in temporary government housing, Soliman is still enthusiastic about the technology and is re-building a solar heater and biogas digester for his new home.

“I’m planning to collect the organic waste from restaurants in the neighborhood to increase my gas output,” he told IPS News. “I’ll give the restaurants plastic bags and they can separate out the organics, and I’ll collect the bags at the end of each day.”

Published: January 2010

Resources

1) Practical Action has technical drawings and guidelines for making a small biogas digester. Website: http://practicalaction.org/practicalanswers/product_info.php?products_id=42

2) The Anaerobic Digestion Community: Here is an excellent technical explanation of how a digester works, including a short film. Website: http://www.anaerobic-digestion.com/

3) China boasts a fast-growing biogas economy using farm waste. Here is a full summary of their experience. Website: http://www.i-sis.org.uk/BiogasChina.php.

https://davidsouthconsulting.org/2022/09/28/asian-factories-starting-to-go-green/

https://davidsouthconsulting.org/2022/09/27/caribbean-island-st-kitts-goes-green-for-tourism/

https://davidsouthconsulting.org/2021/01/25/creating-green-fashion-in-china/

https://davidsouthconsulting.org/2021/08/29/indian-business-model-makes-green-energy-affordable/

https://davidsouthconsulting.org/2021/10/22/innovations-in-green-economy-top-three-agenda/

https://davidsouthconsulting.org/2021/08/07/mongolian-green-book/

https://davidsouthconsulting.org/2022/04/14/prisons-with-green-solutions/

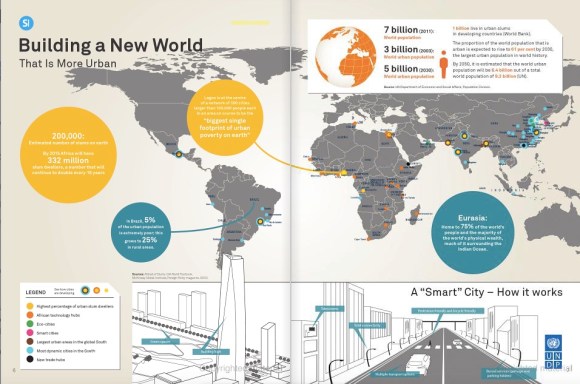

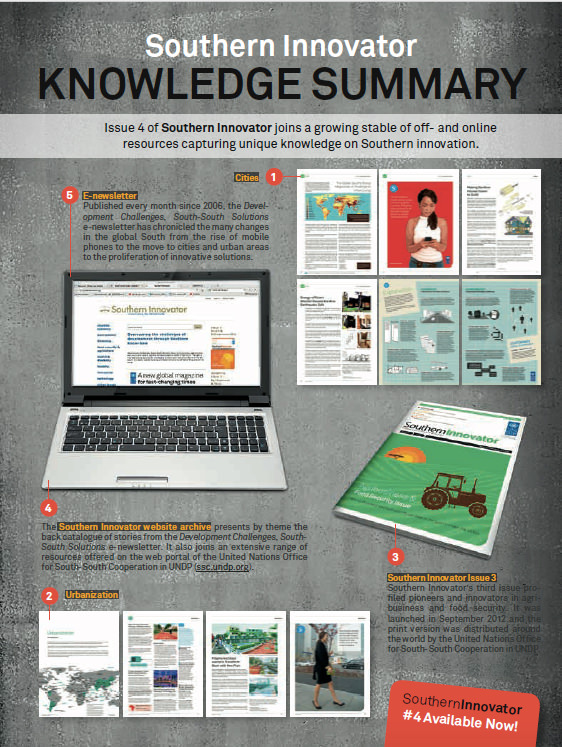

Development Challenges, South-South Solutions was launched as an e-newsletter in 2006 by UNDP’s South-South Cooperation Unit (now the United Nations Office for South-South Cooperation) based in New York, USA. It led on profiling the rise of the global South as an economic powerhouse and was one of the first regular publications to champion the global South’s innovators, entrepreneurs, and pioneers. It tracked the key trends that are now so profoundly reshaping how development is seen and done. This includes the rapid take-up of mobile phones and information technology in the global South (as profiled in the first issue of magazine Southern Innovator), the move to becoming a majority urban world, a growing global innovator culture, and the plethora of solutions being developed in the global South to tackle its problems and improve living conditions and boost human development. The success of the e-newsletter led to the launch of the magazine Southern Innovator.

https://davidsouthconsulting.org/2022/11/01/southern-innovator-magazine-2010-2014/

This work is licensed under a

Creative Commons Attribution-Noncommercial-No Derivative Works 3.0 License.

ORCID iD: https://orcid.org/0000-0001-5311-1052.

© David South Consulting 2023

You must be logged in to post a comment.