By David South, Development Challenges, South-South Solutions

More than 1 billion people around the world lack decent shelter. Of these, the majority live in urban areas, usually in slums and informal settlements (UN-HABITAT). Latin America has a serious shortage of adequate housing: in Colombia, 43 percent of the population needs decent housing; in Brazil, 45 percent; Peru, 53 percent.

The challenge is to provide good quality homes without significantly harming the environment – and with constrained budgets. Bamboo – cheap, strong, quickly renewable and beautiful to look at (http://en.wikipedia.org/wiki/Bamboo) – is an ideal solution to replace traditional wood lumber. In Bolivia, pioneering work is underway to improve the quality of homes and buildings made with bamboo.

Bamboo is the fastest growing woody plant in the world, sometimes growing over 1 metre a day. Bolivia (http://en.wikipedia.org/wiki/Bolivia) has about 17 identified bamboo species, of which five have a significant economic value. Around the world, there are 1,000 species of bamboo. They grow in a wide variety of climates, from cold mountains to hot tropical regions.

Once called the “poor man’s timber” – a temporary building material to replace once there is more money – bamboo is now getting the respect it deserves. Bamboo for housing has a long history in Latin America, stretching back 4,500 years to ancient civilizations. In Asia, it has long been a traditional construction material. But most of the existing bamboo dwellings in Latin America are 50 to 100 years old.

The most popular species of bamboo used in South America is Guadua, which is known for being large, straight and attractive.

“In Bolivia, there is no other building material more competitive in costs,” said Jose Luis Reque Campero, coordinator of the Bolbambu Programme of the Architectural Research Institute, Universidad Mayor de San Simon, Bolivia (http://www.umss.edu.bo/).

“Bamboo is the material that requires less energy, followed by wood and concrete, with steel in last place, needing energy necessary for its production 50 times greater than that required by bamboo.”

Campero also says bamboo is much less expensive than traditional building materials.

“But the biggest advantage is certainly the possibility of planting bamboo, and then reaping houses,” he said.

Campero has focused his efforts on a key component of bamboo housing: the joints that bind the bamboo poles together. Driven by the desire to find ways to improve the ease of building bamboo homes and their strength, Campero came up with the Bamboo Bolivia Space Structures, Structural System: EVO (BBSS-EVO) (named after Bolivia’s president, Evo Morales – http://en.wikipedia.org/wiki/Evo_Morales).

Traditional joints took a long time to make and required power tools and complex instruction manuals. Simplifying the building techniques necessary for bamboo construction was important because, while bamboo was cheap, the labour costs were high.

The joint looks like a giant two-headed Q-Tip. Each end is made of four pieces of bamboo, connected by a long screw with bolts on each end taken from old cars. The joint is inserted inside the bamboo poles and snaps shut, joining poles tightly together and, as each piece is assembled, looking like a child’s building toy as the structure of the bamboo home takes shape.

The new joint was easier to assemble and was quickly adopted by local builders. It also allows for a vast range of structures and shapes to be built, limited only by imagination and physics.

Devising joints made from bamboo has the advantage of avoiding the weight and cost of bringing in concrete, especially to remote areas.

“The manufacturing process is fully in the workshop and indoors,” said Campero, “which in addition to allowing a degree of quality control in production, improves working conditions for staff and protects the material.”

The whole building process adheres to “the principles of the famous phrase: ‘do-it-yourself’.”

The Evo joint allows for flexibility and easy assembly and disassembly, enabling the builder to move around parts of the structure and not be wedded to the original structural plan. This has the advantage of customizing the building to its physical location.

Working in the tropical forests of Cochabamba (http://en.wikipedia.org/wiki/Cochabamba), Campero has been testing his designs with the local people, who were looking to improve the tourist infrastructure in the resort town of Cristal Mayu.

Costa Rica in Central America – ironically a country without indigenous bamboo plants – has used its National Bamboo Project of Costa Rica (http://www.unesco.org/most/centram1.htm) to prove it is possible to both cultivate bamboo and use it to provide housing for the poor, confirming the wisdom of millions of people: bamboo is economical, convenient, safe and looks great.

Campero has received a great deal of interest in his innovations and is looking for funding partners in 2009 to take his work further.

He has this advice for other builders and designers: “Stick to developing local technologies, use what you have and innovate, use native materials and the local environment for the development of elements, components and construction systems. Don’t rely on advanced technology tools for manufacture, and stay in harmony with the human need for creativity.”

Published: December 2008

Resources

- UNEP, the UN’s Environment Programme, has produced a report on bamboo biodiversity and how it can be preserved. Website: http://www.unep-wcmc.org

- The Asian Development Bank is using its Markets for Poor programme to link bamboo products to marketplaces, helping poor communities. Website:http://www.markets4poor.org/

- The United Nations Human Settlements Programme, UN-HABITAT, is the United Nations agency for human settlements. It is mandated by the UN General Assembly to promote socially and environmentally sustainable towns and cities with the goal of providing adequate shelter for all. Website: www.unhabitat.org

https://davidsouthconsulting.org/2022/10/26/bamboo-becomes-transport-option-for-the-south/

https://davidsouthconsulting.org/2021/11/11/decent-and-affordable-housing-for-the-poor/

https://davidsouthconsulting.org/housing/

https://davidsouthconsulting.org/2022/11/16/housing-innovation-in-souths-urban-areas/

https://davidsouthconsulting.org/2021/11/11/housing-solution-for-worlds-growing-urban-population/

https://davidsouthconsulting.org/2022/11/17/tiny-homes-to-meet-global-housing-crisis/

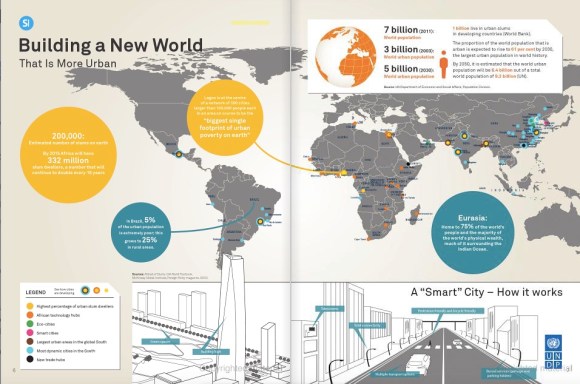

Development Challenges, South-South Solutions was launched as an e-newsletter in 2006 by UNDP’s South-South Cooperation Unit (now the United Nations Office for South-South Cooperation) based in New York, USA. It led on profiling the rise of the global South as an economic powerhouse and was one of the first regular publications to champion the global South’s innovators, entrepreneurs, and pioneers. It tracked the key trends that are now so profoundly reshaping how development is seen and done. This includes the rapid take-up of mobile phones and information technology in the global South (as profiled in the first issue of magazine Southern Innovator), the move to becoming a majority urban world, a growing global innovator culture, and the plethora of solutions being developed in the global South to tackle its problems and improve living conditions and boost human development. The success of the e-newsletter led to the launch of the magazine Southern Innovator.

This work is licensed under a

Creative Commons Attribution-Noncommercial-No Derivative Works 3.0 License.

ORCID iD: https://orcid.org/0000-0001-5311-1052.

© David South Consulting 2023

You must be logged in to post a comment.